Services We Offer

Comprehensive Sourcing Solutions

Explore our tailored services designed to meet the diverse sourcing needs of global apparel brands and retailers.

01

Design and Product Development

Our services help our clients transform their ideas into sample prototypes, even working together with manufacturers to transform a sketch on a napkin into a complete tech pack. We then oversee the various revisions until our client as the exact prototype they specified for production and bring their designs to reality.

02

Sourcing and Manufacturing

Our sourcing and manufacturing selection process is meticulous, connecting clients with vetted manufacturers who meet compliance standards, fostering quality production and timely deliverables in every partnership.

03

Quality Control & Assurance

We put a lot of emphasis on quality products and quality management. Therefore, the planned and systematic activities are implemented in a quality system, so that quality requirements for the garments are fulfilled. Our Quality Assurance also includes management of the quality of raw materials, fabric and color composition, products and components, services related to production, and inspection processes.

>>> Tested quality control processes along with inspections at regular intervals allow us to deliver orders on time and within the required quality standard (AQL 1.0 3 4.0).

>>>We enforce standards from the start 3 fabric, trims, processing (printing + dyeing), lab testing (physical + chemical), patterns & fitting, washing, finishing, packing, in-line (10% packed), mid-line (50% packed), final (100%packed).

>>>Our team includes specialized controllers for eachdifferent and specific product category. Our controller's base experience comes from having manufactured the products by themselves and knowing everything there is to know about them.

04

Sustainability

OUR RESPONSE

We actively promote and participate in efforts to improvesustainability. It is NOT just fashion that is simply made fromsustainable materials. The responsibility goes further thanthis, and spans across the entire value chain.

>>>

Better Cotton Initiative (BCI), making globalcotton production better for the people who produce it, better for the environment it grows in, and better for the sectors future.

>>>Oeko-Tex standards, certifying products are freeof harmful chemicals and are safe for humanuse.

>>>Global Organic Textile Standard (GOTS), processing standard for organic fibers, including ecological and social criteria, backed up by independent certification of the entire textile supply chain.

>>>Global Recycled Standard (GRS), intended for companies making and selling products with recycled content. This standard applies to the full supply chain and addresses traceability, environmental principles, social requirements, and labeling.

05

Logistics/Shipping

We provide comprehensive logistics solutions, managing the entire shipping process to ensure timely delivery while minimizing risks and costs.

06

Compliance

>>>Manufacturing facilities are engineered based on global bench-markedstandards. All our facilities are audited and certified to be compliant with the strictest social and environmental requirements and standards.

>>>It is our responsibility to care. What happens is up to alpine as well as the customer. We have to find the safest/compliant and best suppliers possible. Our customers have to be aware that safety and quality must have a slightly higher price. It9s unavoidable.

>>>ItWe strictly maintain the basic core areas that social compliance should include are policies on child labor, health and safety, forced labor, compensation, discrimination, working hours, discipline, management systems, and the right to free association and collective bargaining. In addition to these core areas, local culture and government regulations also become a part of social compliance in the industry.

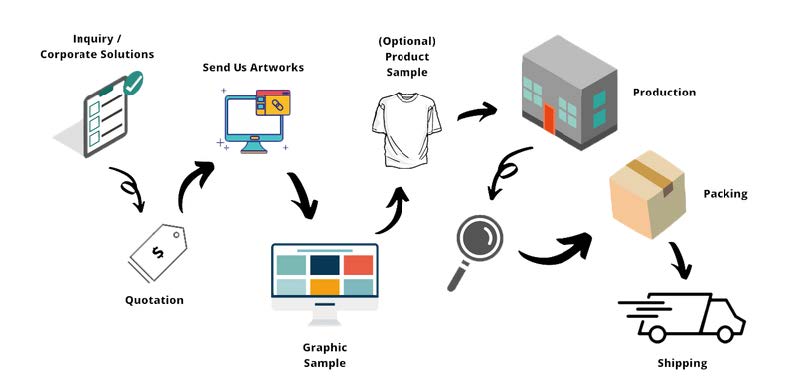

Order Progressing Process

Receiving Order

On receipt of orders based on the above description, discussing with suppliers on process planning, preparation of critical path by highlighting stages involved.

Production Monitoring

Monitoring the production is one of our main services to our clients because once the product cut wrong it will stitch wrong, so we do monitor every step deeply, from fabric, it’s dyeing, the shrinkage, the patterns, the cutting layers, bundling, distribution on the machines, general checking, washing, cropping, pressing, final checking, tags/stickers placements etc, so nothing will be left which will make problem for our clients.

Weekly Progress Report

A meeting with Merchandising, Quality Controller and Logistic staff will be held every Sunday, and this status will be e-mailed to customers every Monday. This will enable all the customers to verify their order progress.

Start Your Sourcing Journey

Contact us today to discover how we can elevate your sourcing operations and help you achieve remarkable results.